VEDAQ-P

VEDAQ-P™ Stationary EMI Inspection System for drill pipe up to 6-5/8" O.D.

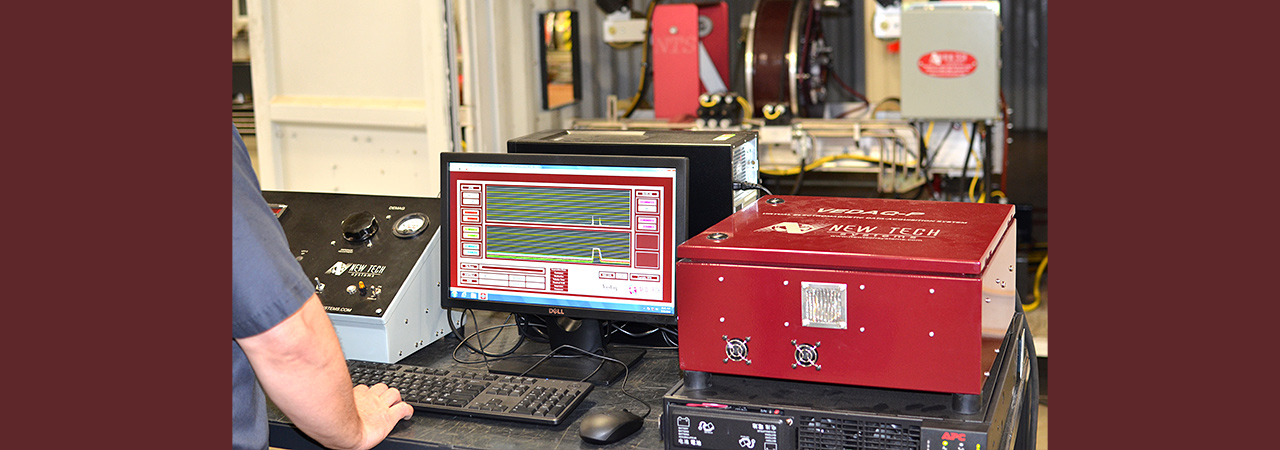

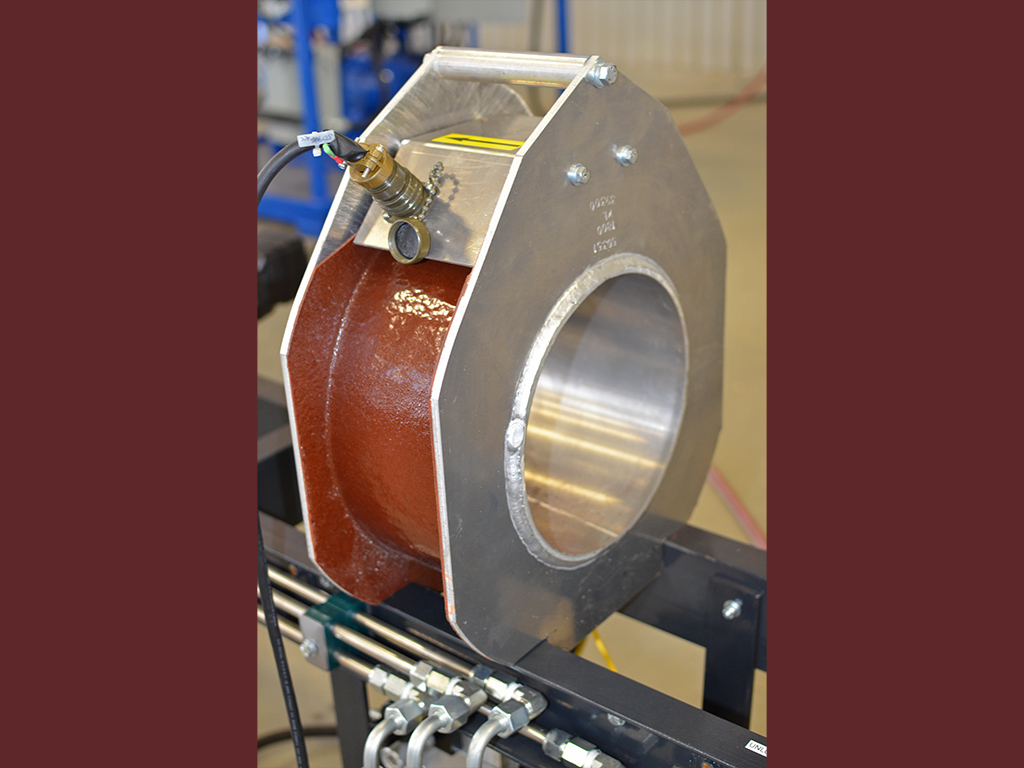

The VEDAQ-P™ is a stationary, computerized, multi-function EMI system for inspecting drill pipe up to 6 5/8" O.D. Transverse flaw detection and TRUEWALL™ (Hall effect) wall monitoring functions are standard on the VEDAQ-P™. The computerized electronics system, heavy-duty center section, pipe handling conveyors, and affordable price make the VEDAQ-P™ the best stationary drill pipe inspection system in the industry. The inspection results are displayed digitally in the software with individual channel colors for easy interpretation. The VEDAQ-P™ provides the operator with a very diversified, sophisticated, and operator-friendly inspection system. The VEDAQ-P™ is designed to meet most industry requirements set forth by API, DS-1, etc.

This system is available in a portable configuration for increased mobility Learn more about the VEDAQ-PRO.

Product Specifications

| Technical and Performance Data | |

| Capacity: | 2 3/8" to 6 5/8" O.D. drill pipe |

| Functions: | Transverse flaw detection (MFL) TRUEWALL™ magnetic wall thickness monitoring (MFD) Demagnetizing system (optional) |

| Data Acquisition: | Data acquisition system with desktop computer (multi-color data display) |

| Production Rate: | 60 to 90 ft. per minute, (all functions) |

| Inspection Criteria: | The VEDAQ-P™ system is designed to meet most stringent industry requirements set forth by API, DS-1, etc. |

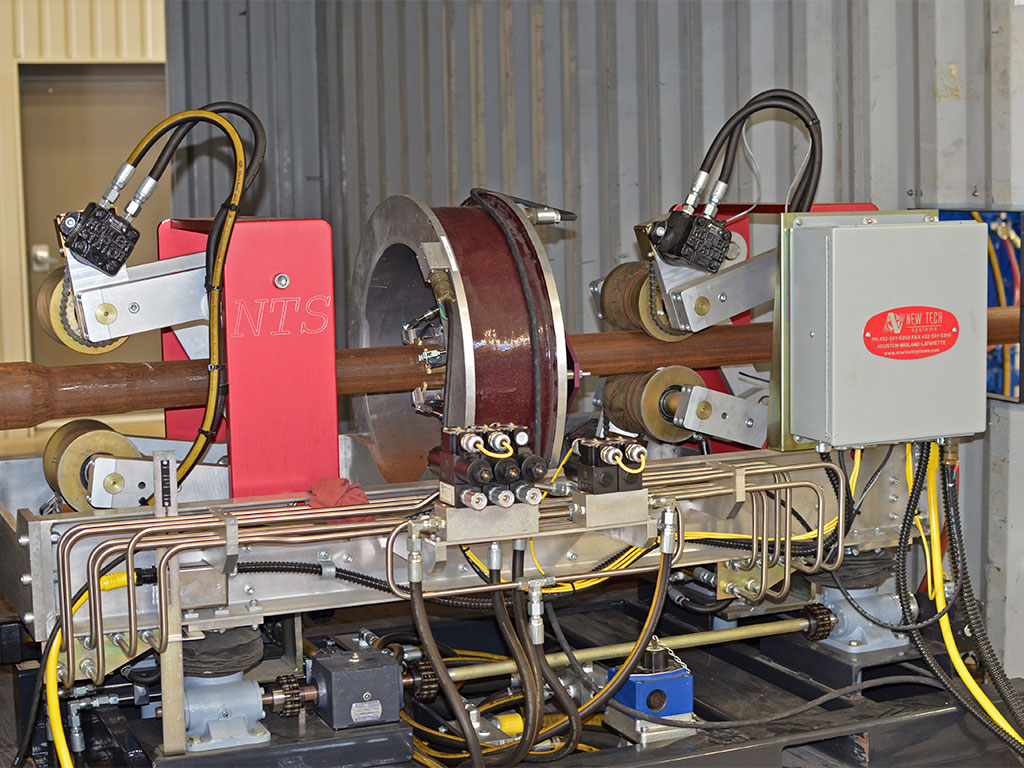

| Major Components: | Computerized electronics system Operators panel Skid-mounted center section Inspection heads (sizes optional) Calibration standards (sizes optional) Conveyors with adjustable stands Conveyor load and unload arms Hydraulic power unit |

| Available Options: |

Demag system Bi-directional load and unload arms Additional conveyors Inspection building (operator compartment) Auto-load racks Onsite training Professional installation |

Product Images

Mode of Operation

At the start of each job, the system is calibrated using a standard reference. Hydraulic pipe arms lift each pipe from the racks and load it onto the infeed conveyors. Hydraulic pinch rollers then automatically open and close to center the pipe precisely within the magnetizing coil. This alignment process can be performed either automatically or manually via switches located in the operator’s compartment.

Once aligned, the pinch rollers clamp onto the pipe and advance it through the system’s center section, where it passes through the magnetizing coil and the airhead assembly, which houses both the transverse flaw detection and magnetic wall thickness monitoring sensors. During inspection, real-time data is displayed digitally, and the operator actively monitors system performance through the interface.

After inspection, the pipe is automatically transferred to the outfeed conveyors for unloading, and the process repeats with the next pipe. An optional demagnetization unit can be integrated to enhance system capabilities.

The VEDAQ-PRO™ is engineered for high production throughput, superior inspection accuracy, and long-term operational reliability.